Friction welding process

Friction welding is a solid-state welding method to realize welding.

The main advantages of friction welding technology can be summarized as follows:

(1)The quality of joint surface high and stable. The welding process is automatically controlled by the machine and easily monitored after the parameters are set. There will be no crystal defects in the cast structure such as porosity segregation and inclusion and cracks in the weld.

(2)High efficiency.High degree of automation of welding equipment, each welding time in seconds, generally only costs a few seconds to dozens of seconds.

(3)Energy saving, material saving, low consumption.The power required is only 1 / 5 / 1 / 15 of the conventional welding process, without electrode, flux, protective gas, no need metal addition, or electrode consumption.

(4)Good weldability. Especially suitable for welding of different materials, such as steel and copper, steel and aluminum, steel and brass etc.

(5) Environmental protection, no pollution.The welding process produces no smoke or harmful gas, no spatter, no solitary light and sparks, no radiation.

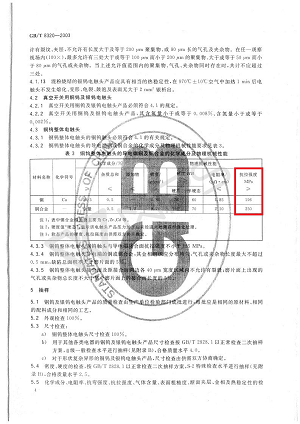

Joint strength of friction welding processReferring to the national standards of GB/T 8320-2003 copper-tungsten and silver-tungsten electric contacts and the technical conditions of OKA.889.067-2006 contact elements, the strength of copper-tungsten bonding surface is determined to be CuW/T2-Y ≥ 196MPa , CuW / QCr0.5 ≥ 226MPa, and it is suggested that the strength of friction welded joints be determined as Cu/T2-Y ≥ 196MPaU,CuQCr0.5 ≥ 196MPa, QCr0.5/QCr0.5 ≥ 250MPa.

Process verification process: friction welding →Coloring flaw detection and weld metallography →Tensile test→Data consolidation